English

Views: 0 Author: Site Editor Publish Time: 2025-12-04 Origin: Site

In today’s dynamic industrial and commercial environments, protecting equipment, materials, and infrastructure from moisture damage is more critical than ever. Whether in temporary storage, construction sites, data centers, or production floors, uncontrolled humidity can lead to corrosion, mold, material degradation, and costly downtime.

Enter the mobile dehumidifier—a versatile, powerful, and increasingly essential tool for moisture control across varied environments. Unlike fixed or centralized systems, mobile dehumidifiers offer the unique advantage of portability, allowing humidity management wherever it's needed most.

Many industrial processes and sensitive storage applications require strict control of ambient humidity levels. However, not all of these environments are permanent or stationary. For instance:

Construction projects often shift from site to site.

Temporary storage areas or containers may not have built-in climate control.

Emergency response operations (e.g., after flooding or water damage) demand immediate and mobile drying solutions.

Seasonal variations in humidity can affect warehouses and production zones unpredictably.

In such cases, traditional standalone dehumidifiers—though powerful—are often limited by their fixed nature. Mobile dehumidifiers fill this gap by offering flexibility without compromising on performance.

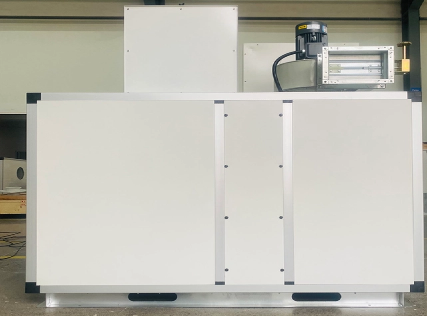

A mobile dehumidifier is a self-contained, portable unit designed to remove moisture from the air in various environments. These units typically come mounted on wheels or equipped with handles, making them easy to transport and deploy quickly.

Mobile units are available in various capacities, ranging from compact models for small rooms or equipment enclosures to industrial-grade versions capable of handling high humidity loads in large spaces.

Like their stationary counterparts, mobile dehumidifiers operate using one of two primary methods:

These systems cool air to condense moisture, which is then collected in a tank or drained away. They are energy-efficient and ideal for warm, humid conditions.

These use materials like silica gel to absorb moisture. Desiccant systems perform exceptionally well in cold or low-humidity environments, making them ideal for winter construction or cold storage areas.

High-end mobile units may combine both technologies or include features like:

Digital humidity controls

Remote monitoring

Multiple airflow settings

Continuous drainage systems

The most obvious benefit is the ability to move the unit where it’s needed most. This is invaluable for operations that change locations or where localized moisture issues arise.

Mobile units can be used across various sites—drying out a freshly painted room one day, preventing condensation in a temporary storage tent the next.

In emergency scenarios such as water ingress, burst pipes, or flooding, mobile dehumidifiers can be deployed quickly to minimize moisture-related damage.

Instead of installing multiple permanent units in rarely used zones, a single high-capacity mobile unit can be rotated as needed—optimizing both investment and energy usage.

Even in facilities with centralized HVAC or standalone dehumidifiers, mobile units serve as excellent backups or targeted reinforcements in high-risk areas.

While the terms are sometimes used interchangeably, there are distinctions between mobile dehumidifiers and traditional standalone dehumidifiers:

Feature | Mobile Dehumidifier | Standalone Dehumidifier |

Mobility | Designed for frequent movement | Usually stationary, heavier units |

Use Case | Temporary or dynamic spaces | Fixed location like basements or rooms |

Size Options | Compact to industrial-grade | Mostly medium to large |

Installation | Plug-and-play, no installation needed | May require drainage or duct setup |

Flexibility | High | Moderate |

In practice, many facilities use both. Mobile units serve as on-demand tools, while standalone systems provide background moisture control.

Protect building materials from moisture damage, accelerate drying times for paint and plaster, and ensure safe work conditions.

Maintain critical humidity levels in mobile storage tents, labs, or during transit to prevent contamination and product degradation.

Safeguard sensitive inventory in temporary storage areas or during seasonal shifts in humidity.

Control moisture in high-tech environments to prevent corrosion or static build-up.

Dry out structures quickly after floods, leaks, or fire suppression to prevent mold growth and structural damage.

As sustainability becomes a priority for businesses worldwide, modern mobile dehumidifiers are evolving to meet the demands for both energy efficiency and environmental responsibility. Manufacturers are integrating advanced technologies and eco-friendly designs to minimize power consumption while maintaining optimal humidity control. These improvements not only reduce operating costs but also help facilities lower their carbon footprint.

Key energy-saving features in contemporary mobile dehumidifiers include:

Eco-Mode and Humidity Sensors for Optimized Operation: Many mobile units now come equipped with intelligent control systems that continuously monitor ambient humidity levels. These sensors enable the device to operate only when necessary, automatically adjusting output to maintain target conditions without wasting energy. The Eco-mode further fine-tunes performance by modulating fan speeds and compressor cycles, ensuring that the unit runs at peak efficiency rather than full capacity all the time.

High-Efficiency Rotors and Compressors: Advances in motor and compressor technology have significantly improved the energy efficiency of dehumidifiers. High-performance compressors and low-friction rotors consume less electricity while delivering the same or better moisture removal rates. These components also tend to generate less heat and noise, contributing to a more comfortable warehouse environment.

Waste Heat Recovery in Desiccant Models: Desiccant dehumidifiers, which use absorbent materials to extract moisture, are increasingly designed to recycle and reuse waste heat generated during the drying process. This heat recovery reduces the overall energy required to regenerate the desiccant material, lowering fuel or electricity consumption and boosting system efficiency.

Low-GWP (Global Warming Potential) Refrigerants: Environmental regulations are pushing industries toward refrigerants that have minimal impact on global warming. Modern mobile refrigerant-based dehumidifiers use low-GWP refrigerants such as R-32 or R-1234yf, which help reduce greenhouse gas emissions compared to older refrigerant types. This shift aligns warehouse operations with international sustainability goals and may contribute to corporate environmental responsibility reporting.

Reduced Reliance on Larger Climate Control Systems: By effectively managing humidity in localized zones, mobile dehumidifiers often lessen the need to run large-scale HVAC systems at full capacity. This downsizing reduces overall facility energy consumption and operational costs. In turn, it lowers the facility’s carbon footprint, making mobile dehumidification a key element in greener warehouse management.

These innovations ensure that modern mobile dehumidifiers deliver high performance without compromising environmental commitments. For warehouses seeking to balance operational efficiency with sustainability, investing in energy-efficient mobile dehumidification technology can be a crucial step toward greener, more cost-effective operations.

Whether you're managing a growing facility, handling sensitive materials, or dealing with unpredictable environments, a mobile dehumidifier provides unmatched flexibility, protection, and value.

For businesses that require customized mobile or standalone dehumidification solutions, working with a knowledgeable and experienced manufacturer is key. Companies like Hangzhou Peritech Dehumidifying Equipment Co., Ltd. specialize in industrial-grade dehumidification equipment, offering tailored systems to suit your operational needs.

To learn more about their innovative technologies, project experience, or how to select the right system for your facility, consider reaching out to their technical team for professional insight and support.